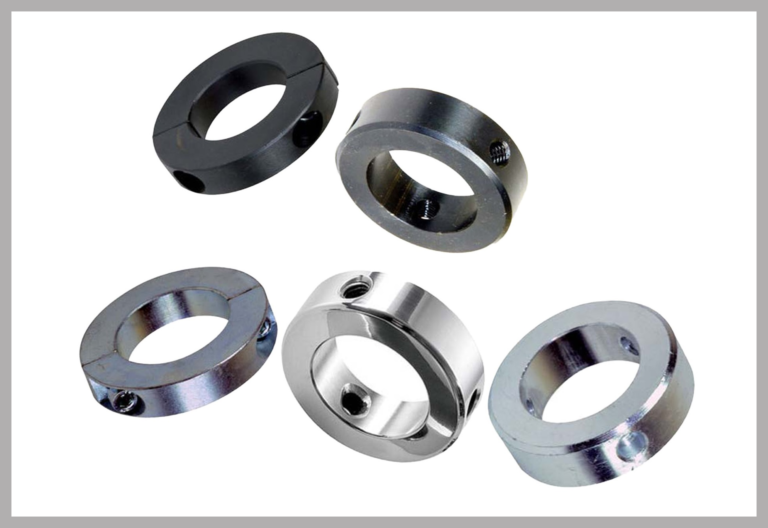

Shaft Collars

Shaft collars, also known as locking collars or shaft clamps, are essential components in various industries. These circular metal devices fit onto a shaft and serve critical functions like securing gears, pulleys, sprockets, bearings, or any other rotating components, or acting as mechanical stops.

There are two primary types of shaft collars: set screw and clamp collars, each with its unique method of attachment.

Set screw collars are affixed to the shaft using screws that bite into the shaft’s surface. While they offer impressive holding power and torque capacities, they can damage the shaft, making repositioning or removal challenging.

In contrast, clamping collars use compression to mount onto the shaft securely. They are preferred for their ease of installation and non-damaging nature to the shaft. Clamping collars distribute force evenly on the shaft, providing exceptional holding power. They come in one-piece and two-piece designs, offering flexibility based on installation requirements.

One-piece shaft collars utilize screw clamps and are suitable for split hub applications. Two-piece collars offer convenience in installation, especially in challenging situations.

Shaft collars come in various shaft diameters, measured in millimetres. Regardless of whether they are screw or clamp versions, well-designed shaft collars ensure precise and reliable attachment to the corresponding shaft.

These collars are available in steel, stainless steel and also available with a black phosphate finish, catering to diverse industrial needs and environmental conditions.

Please fill in the form below to get your Shaft Collar catalogue.

Should you require further information please feel free to call: 01233 663340