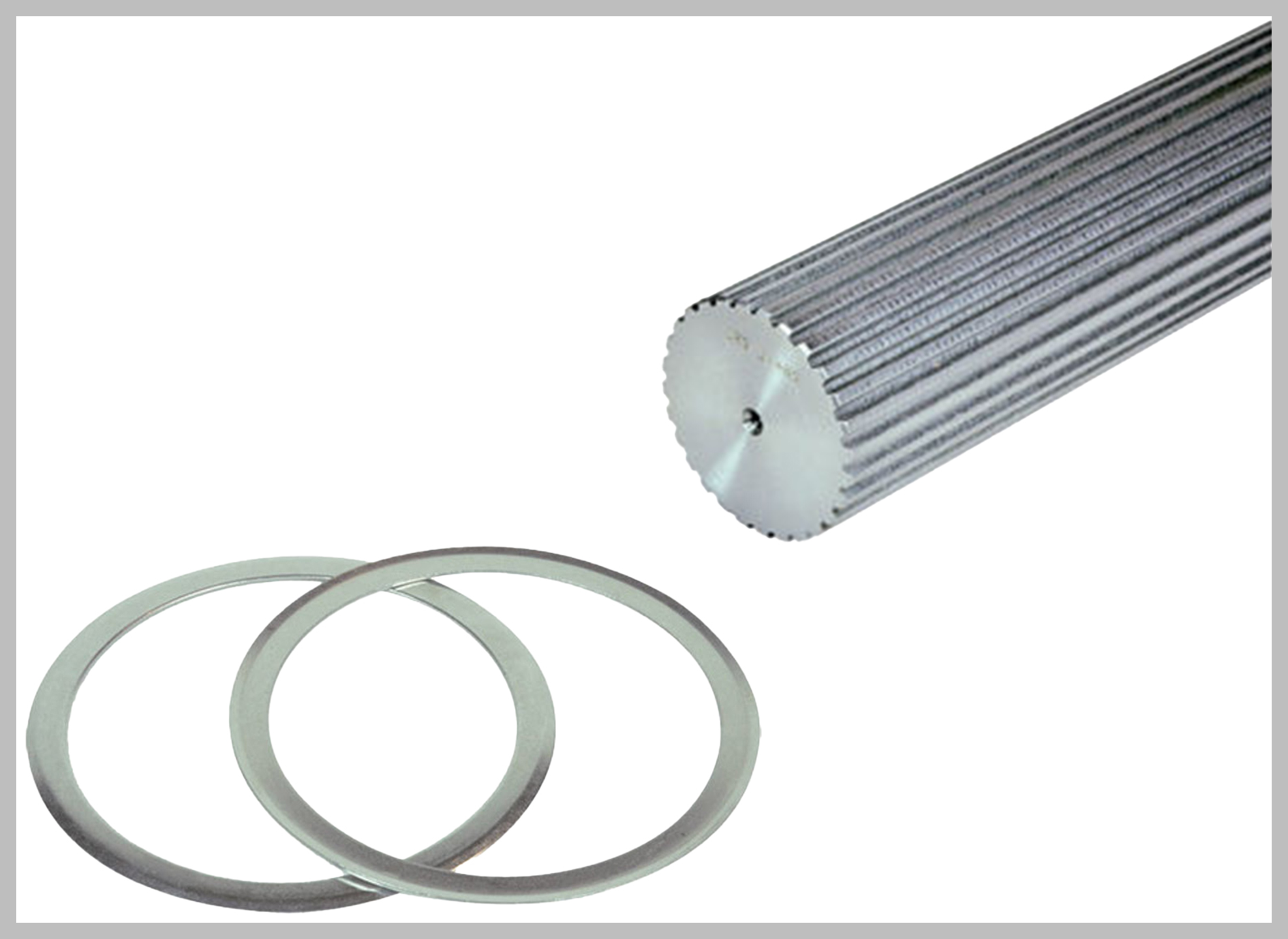

Timing Bars & Flanges

Timing belt bars serve as a semi-finished product for the production of timing pulleys. They are produced in different profiles, which correspond to the belt profiles. The basic types are made of aluminium alloy, alternatively steel and are essential for the following reasons:

Power Transmission: They convert rotational motion from one shaft to another, ensuring that the power is transmitted efficiently without slippage.

Synchronization: The teeth on the timing belt mesh with the grooves on the timing belt bars, ensuring precise timing and synchronization of the rotating components.

Speed Variation: By varying the size of the timing belt bars, different speed ratios can be achieved, allowing for speed control within the system.

Timing belt flanges are typically used on timing belt pulleys to keep the timing belt aligned and prevent it from slipping off the pulley. Their functions include:

Guidance: They guide the timing belt along the pulley’s path, ensuring it stays aligned during operation.

Prevention of Side Movement: They prevent lateral movement of the belt, which can cause misalignment, increased wear, or even system failure.

Stability: They provide additional stability to the timing belt, especially in high-speed applications or systems with varying loads.

Reduced Wear: By keeping the belt properly aligned, flanges reduce the wear on the edges of the belt, prolonging its operational life.

Please fill in the form below to get your Timing Bars & Flanges catalogue.

Should you require further information please feel free to call: 01233 663340